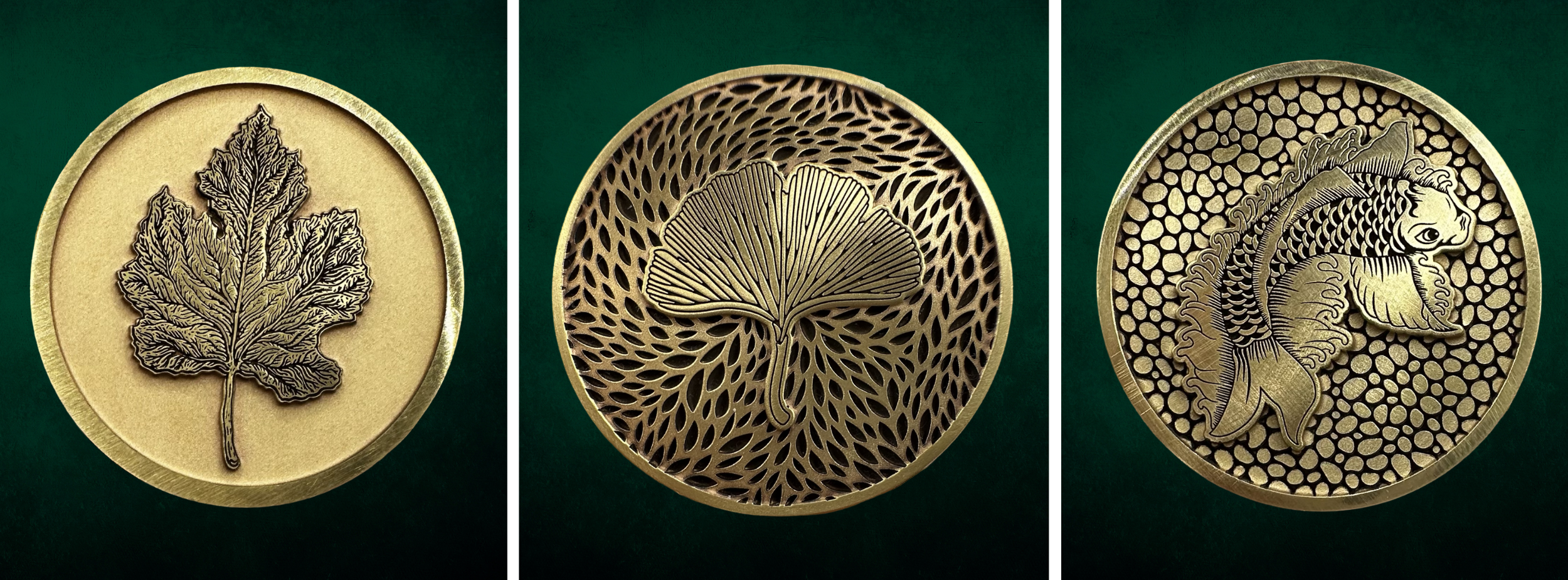

Laser marking and engraving of Ferrous metals including precious metal alloys for the jewelry and Fashion industries offers a permanent and versatile way to customize rings, bangles, bracelets, name necklaces, coins, award coins, badges, wedding bands, pendants, and religious jewelry icons. VTron Laser marking, engraving, and cutting machines are a high-speed, low-impact solution used for a wide range of material processing and by a variety of industries

Today’s laser technology has become the most popular choice for jewelry branding, deep engraving, and adornments, due to their high-efficiency low maintenance cost, ease of operation and extreme reliability, and the lack of consumable requirements. In addition, laser engraving, marking, and cutting systems takes up a small footprint and can be easily integrated into production lines or configurable automation process.

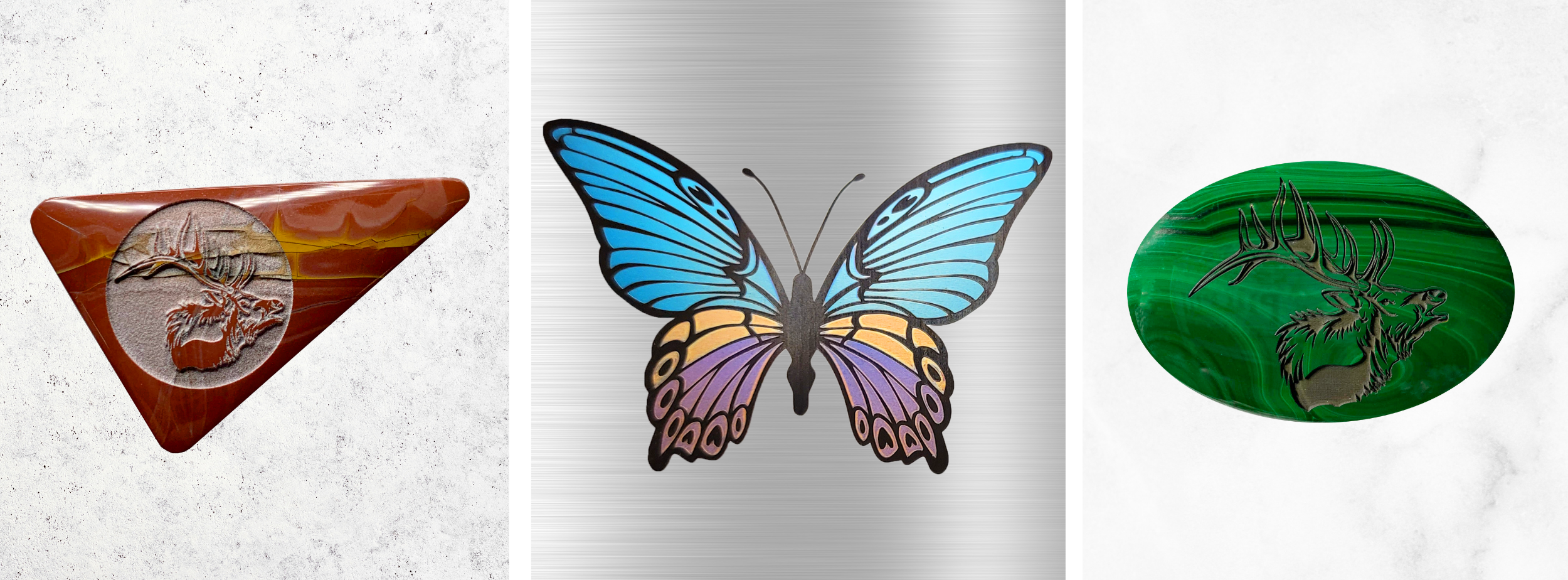

VTron Lasers can engrave, anneal, color, mark, and cut on a variety of substrates in 2D, 2.5D as well as 3D, and on different types of surfaces including, flat, cylindrical, curved, or complex surfaces. Based on the customers’ application VTron Lasers manufactures Galvanometer, Gantry, and full CNC systems for engraving, marking, welding, and cutting to meet the customer’s requirements.

VTron Lasers’ systems come with standard two days of training, and 2 years of technical support, and are backed up by a robust warranty and factory support.

- Arc lamp terminals

- Automotive air bag triggers

- Electrical connectors

- Electrode bonding

- Lithium batteries

- Harness assemblies

- LCD panel contacts

- Microwave modules

- Power CSR

- PCB’s

- Relay terminals

- Smart cards

- Switches

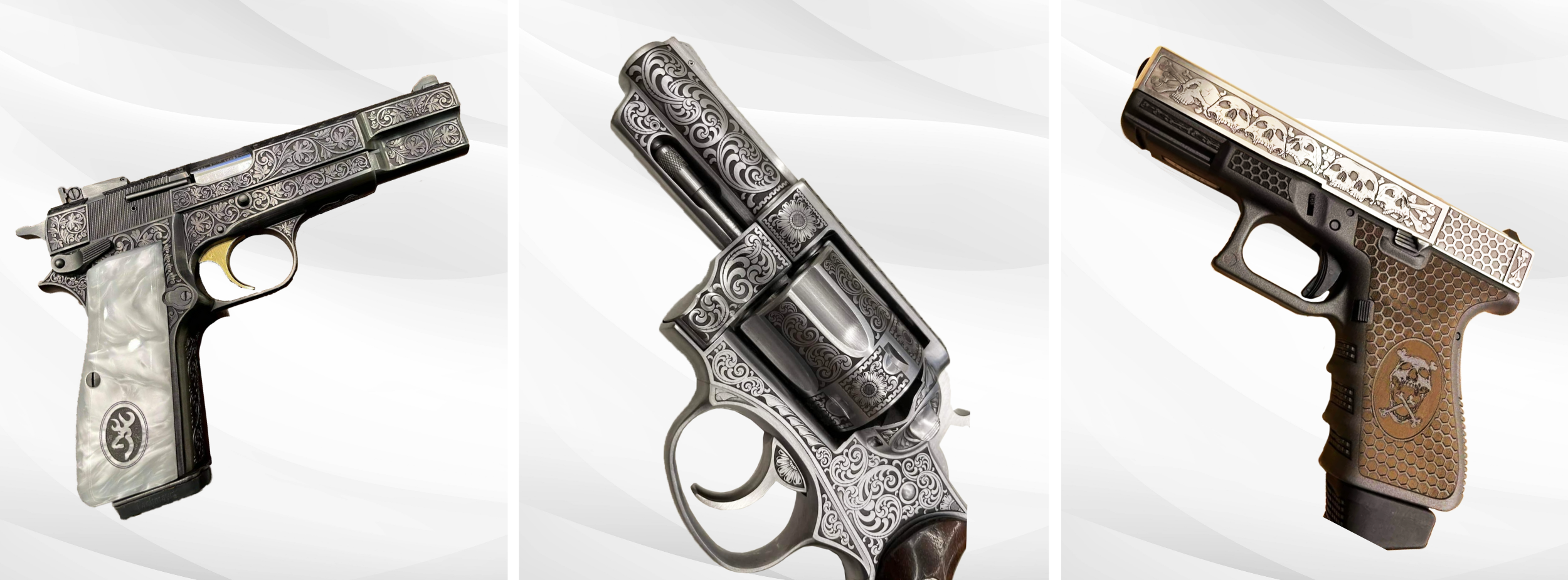

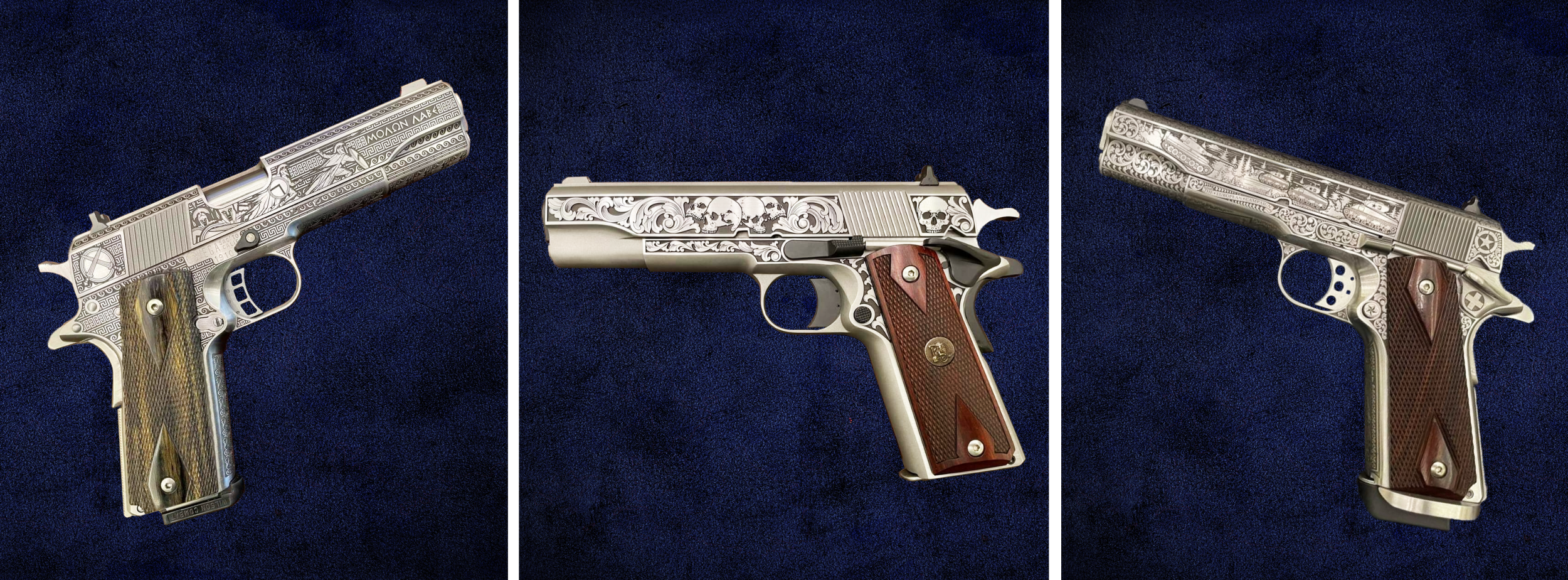

- 2D, 2.5D, and 3D engravings of all gun parts, including slides, magazines, barrels, and lower receivers

- Porting and Cutting Capable on all gun parts

- Cerakote & Duracoat etching and engraving

- Micro engraving/serialization

- Polymer frame/grips stippling in 2D and 3D dimensions

- 3D Logos and Coat of Arms engraving

- Ball bearings

- Bellows

- Chemical injectors

- Level sensors

- High speed rotary tools

- Hot runners

- Motor rotors

- Plastic injection molds

- Pad locks

- Pressure vessels

- Thermocouples

- Solenoid valves

- Ultrasonic sensors

- Assembling bracelets

- Assembly of jewelry

- Bezel building

- Channel building

- Easy re-tipping on gemstones

- Re-tipping prongs

- Refilling casting porosity

- Spot and seam welding

- Resizing ring shanks

- Repairing titanium jewelry

- Optical frames

- Surface polishing

- Welding micro chains and Cuban links

- Welding hollow jewelry

- Adding occlusion

- Cardiac pacemakers

- Catheters

- Defibrillators

- Dental braces

- Dental bridgework

- Endoscopes

- Guide wires

- Hearing aids

- Medical implants

- Orthodontic wire and bands

- Prosthetics

- Ultrasound modules